High-quality Mud Pump Spare Parts Manufacturer – Sgeil

We offer a variety of models of dual-cylinder, triple-cylinder and quintuple-cylinder mud pumps, complete sets of spare parts and complete fluid system solutions. They are suitable for oil and gas, water wells and geological drilling fields. Delivery is prompt, prices are favorable, and they are sold at factory price.

High durability and wear resistance

Stable and reliable performance

Easy installation and replacement

Long service life

Cost-effective and efficient

Select The Appropriate Model Of The Pump Accessories

Match Different Drilling Depths And Working Conditions

Pressure Gauge

- Process: liquid column type, elastic type, and sensor type

- Principle:Converts pressure into liquid column displacement, elastic deformation, or electrical output

- Medium: water, alcohol, mercury

- Application: widely used in industrial systems and oil well drilling equipment

Rubber Sealing Parts

- Temperature: -40°C to 120°C

- Applications: rubber gaskets for drilling pumps

- Properties: aging resistance, chemical resistance

- Performance:high sealing efficiency between 50°C and 120°C

- Features:waterproof, dustproof, soundproof, heat insulation, shock absorption

- Functions:Minimize pressure spikes,Boost pump efficiency,Prevent wellbore leaks

- Discharge Dampers: Smooth flow and pressure

- Suction Dampers: Improve suction, prevent cavitation

- Advantages:Suitable for high-pressure pipelines,Absorbs shocks and water hammer,Prevents pump shutdowns

Air Bag

Cylinder Liner

- Process: high-chromium iron inner sleeve

- Outer sleeve strength (psi): high-strength forged steel design

Inner sleeve - hardness (HRC): ≥61–64

- Working pressure (psi): suitable for oilfield drilling operations

- Service life (hours): long service life

Valve Cover

- Process: 35CrMo alloy steel forging + machining

- Material: 35CrMo

- Outer sleeve tensile strength (psi): high-strength alloy steel design

- Inner sleeve hardness (HRC): N/A

- Service life (hours): long service life

Cylinder Head Flange

- Process: 35CrMo alloy steel forging + machining

- Material: 35CrMo

- Outer sleeve tensile strength (psi): high-strength alloy steel design

Inner sleeve - hardness (HRC): N/A

- Service life (hours): long service life

Cylinder Head

- Process: alloy steel forging + heat treatment + CNC machining

- Material: 35CrMo

- Outer sleeve tensile strength (psi): high-strength alloy steel design

Inner sleeve - Working pressure (psi): suitable for F-series, 3NB-series and other mud pumps

- Service life (hours): long service life

Packing Box

- Process: alloy steel forging + heat treatment + CNC machining

- Outer sleeve tensile strength (psi): high-strength alloy steel design

- Inner sleeve hardness (HRC): N/A

- Working pressure (psi): suitable for API-standard mud pumps

- Service life (hours): long service life

Piston Rod

- Process: alloy steel forging + heat treatment + CNC machining

- Outer sleeve tensile strength (psi): high-strength alloy steel design

- Inner sleeve hardness (HRC): N/A

- Working pressure (psi): suitable for API-standard mud pumps

- Service life (hours): long service life

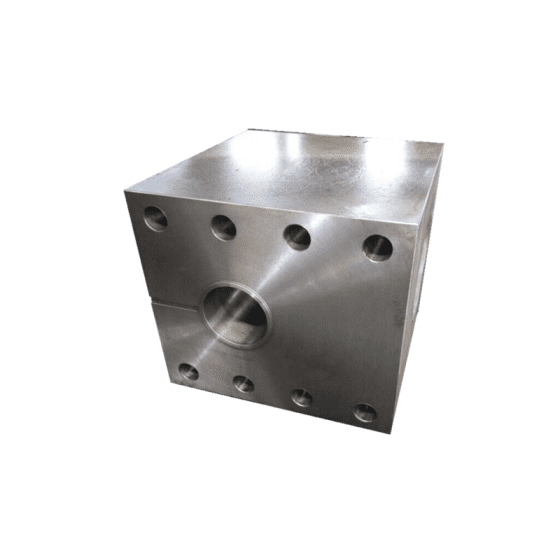

Liquid Cylinder

- Material & Structure:Forged from 35CrMo / 40CrMnMo alloy steel

- Advantages:No welding, defect-free.

- Standard & Strength: Class III forging inspection, high mechanical strength.

- Durability:Heat-treated and hardened, inner wall hardness **HB 285–330**.

- Quality Control:Strict machining and 100% NDT

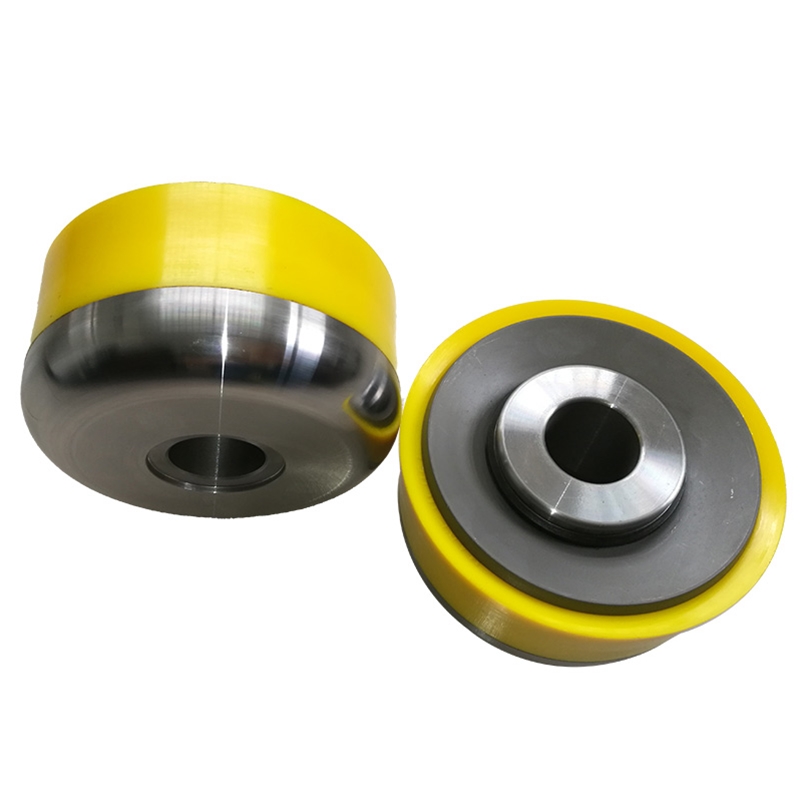

Piston

- Process: forged piston core + molded rubber piston cup

- Piston core material: 42CrMo

- Piston cup material: NBR or polyurethane

- Tensile strength: high tensile strength design

- Wear resistance: high abrasion resistance

If you want to know more about the product models, please contact us. We will recommend the appropriate mud pump models for you.

Application Scenarios

Where Our Spare Parts Work Best

Sgeil mud pumps are widely used in water well drilling rigs, oil drilling, geological exploration, and tunnel construction projects, making them your ideal choice for high-pressure mud pumps. The pump body is solid and durable, made with high-quality alloy materials and advanced heat-treatment technology, ensuring stable and reliable performance even under long-term heavy-load operation. With high pressure and large flow capacity, it adapts to various complex formations, effectively improving drilling speed and reducing operating costs.

Quality Certification

ISO 9001

Quality System Certification

API 7K

Petroleum drilling equipment certification

CE certification

EU safety certification

IADC

Drilling operation technical training

Patent Certification

Mud pump technology patent

What Our Customers Are Saying

Sgeil IS80-65-160 Centrifugal Pump

We installed the IS80-65-160 centrifugal pump in our water treatment process line.

The pump handles clean and slightly contaminated water reliably and maintains stable operation.

Build quality feels solid, and overall performance meets our process requirements.

Emily Carter

QBY3-50 Stainless Steel Diaphragm Pump

The QBY3-50 stainless steel diaphragm pump is used on our vessels for chemical and bilge liquid transfer.

It operates smoothly, resists corrosion well, and is easy for the crew to operate.

We appreciate the stable flow rate and the solid build quality.

Daniel Roberts

Sgeil BW160 mud pump spare parts

We ordered Gardner Denver BW160 mud pump spare parts for our existing rigs.

The parts fit perfectly, are of high quality, and have helped maintain pump performance without any issues.

Their durability has greatly reduced maintenance frequency.

Sophia Williams

Sgeil BW160-9 high-pressure mud pump

We installed the BW160-9 high-pressure mud pump on our drilling rig for continuous mud circulation.

The pump provides stable pressure, handles abrasive drilling fluids well, and maintenance has been simple.

Its reliability has noticeably improved our drilling efficiency.

Michael Thompson

Sgeil Elephant 9P100 mud pump

We have been using the Elephant 9P100 mud pump on our onshore drilling rigs.

It delivers high pressure, runs reliably even under harsh conditions, and maintenance is straightforward.

The pump has significantly improved our drilling efficiency and reduced downtime.

Michael Thompson

Sgeil QW50-20-5.5 Submersible Sewage Pump

The Sgeil QW50-20-5.5 submersible pump is installed in our marine bilge system.

It handles large volumes of water smoothly and operates quietly.

Installation was simple, and we are very satisfied with its reliability in the marine environment.